ink micro flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow Meter CO.,LTD is aprofessional manufacturer of super micro liquid flow meter, oval gear flowmeter , mass flow meter, spur gear flow meter, gear pump, gear metering pump,etc. industrial automation instrumentation design, manufacturing, sales andservice as one of the high-tech enterprises. The company has gathered manyoutstanding engineering and technical personnel, strong technical force,advanced production equipment, complete detection means, and developed a seriesof rigorous scientific production process. Sound quality assurance system, intheir own efforts and the vast majority of users with the strong support ofcontinuous development and expansion , Has achieved the recognition of theindustry, the products are exported to more than 20 provinces, municipalitiesand autonomous regions, and are widely used in electric power, metallurgy,chemical industry, military industry, oil fields, aviation and other fields.

ink micro flow measurement

At presentdomestic Oval gear flow meter structure is complex, bulky, bulky, noisy, smallscale, not suitable for low viscosity liquid, the market is more common withDTO series and OGM series. For these problems the country has been unable toovercome, while the Shanghai JiShen instrument Instrument company oval gear Ovalgear flow meter does not have the above problems, such as the same DN25caliber, our model CX-M25-AL, flow range: 0.5 ~ 100L / M, range of 1: 200 orhigher, and weighs only 1.5KG , While the DTO-25, the flow of 600-6000L / H,range ratio of only 1:10, the weight of up to 23KG. All this due totechnological breakthroughs, our chief engineer Tu workers, he is a formerSiemens senior engineer, the use of equipment It is also Siemens CNC MachiningCenter with cutting accuracy up to 0.001mm, which ensures that we produce highquality flow meters.

Oval gear flow meter, belonging to a type of volumetric flowmeter,cylindrical shape, with import and export, according to the media with a customfilter. Small size, light weight, easy installation, compact structure, withouttoo much maintenance; other The range ratio is very wide, generally more than1: 100, the minimum flow rate can be measured to 0.3ml / min; and thelinearization accuracy can reach 0.5% FS of full scale, so the use is very wideand can be used for measuring, regulating, controlling and distributing Highand low viscosity, or corrosive liquids, and there are health-type,explosion-proof for a special environment.

ink micro flow measurement

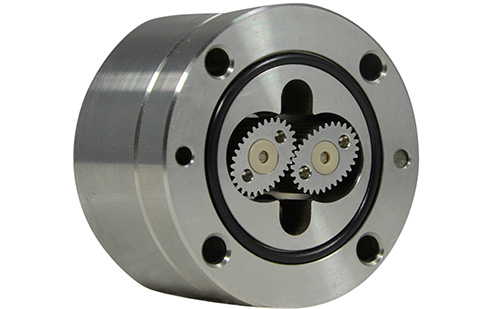

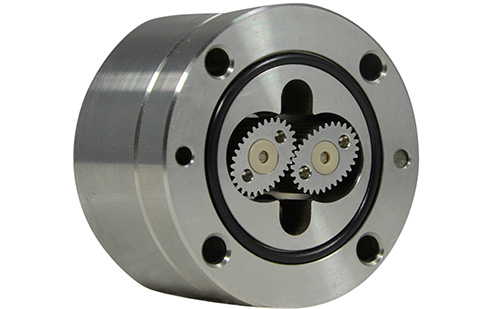

The measuring part of Oval gear flow meter mainly consists of twointermeshing gears and their housings, and the gear generates the acting momentto make it rotate under the pressure difference of the measured medium. Thegears alternately rotate with one another to drive the measured The medium inorder to half the volume of the unit from import to export row by row, so themirco flow meter discharge per revolution measured volume of medium is half thevolume of 4 times the volume flow through the micro-volume flow meter Q Can befigured out

ink micro flow measurement

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

Commonfault causes, troubleshooting

a. Thegear does not rotate: The gear is jammed by debris, the gear and cavity need tobe cleaned, and the filter is cleaned or replaced.

b. Thesmall flow error is too large: The flowmeter is installed in the wrongdirection, the best position goes up and down, or there are impurities to blockthe gear and need to be cleaned.

c. Theflow error is too large: The actual use flow range is less than or far greaterthan the flowmeter range. The corresponding flowmeter must be selected.

d. Noflow sensor signal: The gear is stuck or the circuit is connected incorrectlyor the circuit is damaged. The gear and cavity must be cleaned, or the circuitmust be correctly connected or replaced.